- Home

- /

- Case Studies

- /

- How Datalink Electronics Designed and Prototyped Precision Audio Electronics for a Next-Generation Automotive Sound Platform

How Datalink Electronics Designed and Prototyped Precision Audio Electronics for a Next-Generation Automotive Sound Platform

Client Profile / Background

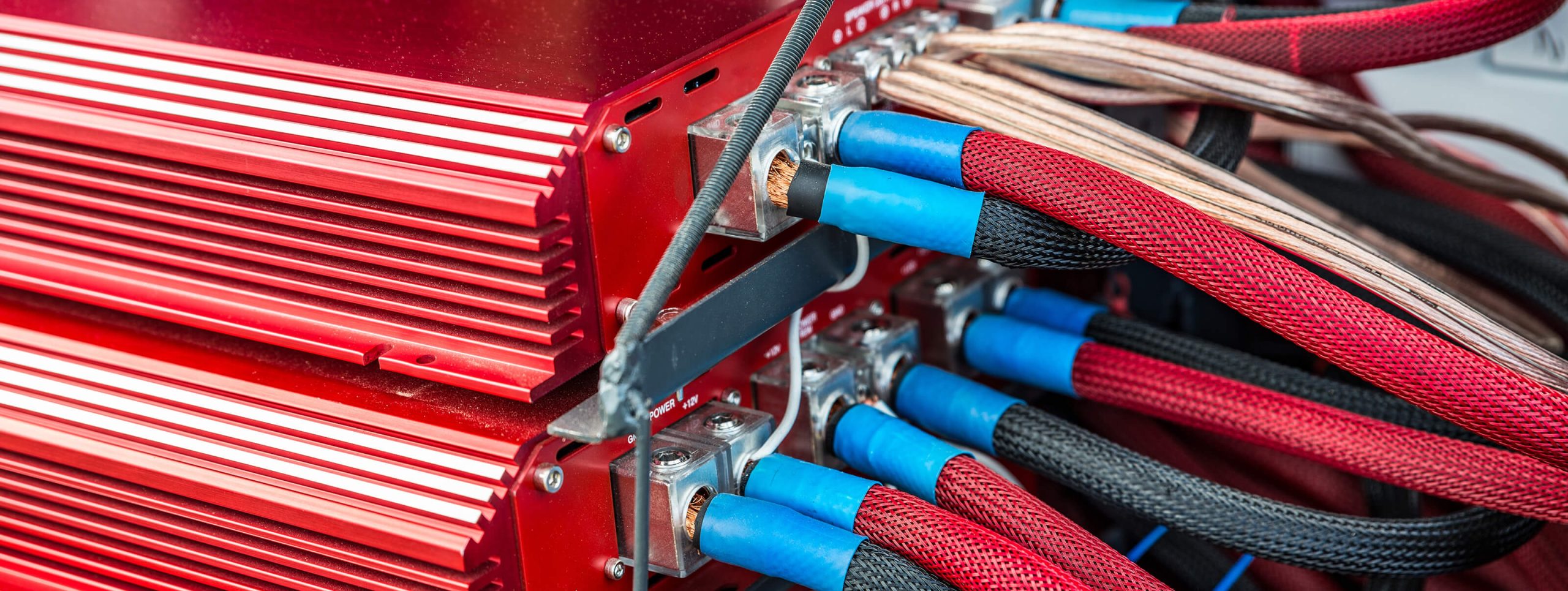

The client’s new acoustic concept required completely new electronic architecture to drive and control its proprietary transducer technology.

Key challenges included:

- Designing low-noise, high-accuracy amplifier and control circuits for pure, distortion-free sound reproduction.

- Creating a compact form factor suitable for integration into multiple vehicle platforms.

- Managing thermal behaviour, EMI resilience, and consistent channel response under automotive operating conditions.

- Enabling fast design iteration and prototype validation to support early-stage R&D and acoustic evaluation.

The goal was to develop and prototype the core control electronics that could later be industrialised for full automotive production.

Datalink’s design and engineering team worked in close collaboration with the client’s acoustic specialists to turn concept-level requirements into a fully functional prototype electronic control module.

Datalink’s Design & Prototype Approach Included:

- Collaborative Concept Development: Worked from early circuit concepts and simulation data to define architecture, component selection, and performance criteria.

- Precision PCB Design: Produced a multilayer board layout optimised for low-noise analogue signal integrity and high channel linearity.

- Rapid Prototyping: Used Datalink’s in-house quick-turn PCB and assembly capability to deliver fully populated prototypes for bench and in-vehicle testing.

- Firmware Integration Support: Collaborated with the client’s DSP team to align control interfaces and calibration parameters.

- Validation & Testing: Conducted electrical performance testing, EMI screening, and thermal mapping to benchmark performance against design targets.

The result was a high-fidelity electronics prototype that demonstrated both technical feasibility and the scalability potential for future production.

- Requirements Definition:

Early workshops clarified performance specifications, integration constraints, and testing methodology. - Design Engineering:

Datalink’s engineers developed schematic designs, simulation models, and prototype layouts optimised for signal clarity and manufacturability. - Prototype Fabrication:

Prototypes were built in-house using controlled processes and automotive-compliant materials for environmental stability. - Testing & Validation:

Each prototype underwent bench validation and acoustic testing to confirm system performance and ensure compliance with EMI/EMC requirements. - Knowledge Transfer:

Datalink provided comprehensive design documentation and prototype test reports to support the client’s internal R&D and next-phase development.

The Results / Outcomes

Technical Achievements:

- Delivered working prototype electronics within a compressed project timeframe, enabling early acoustic system evaluation.

- Achieved low-noise, high-precision performance suitable for luxury-grade automotive audio applications.

- Validated critical parameters including thermal stability, EMI resilience, and power efficiency.

- Provided a scalable design foundation for industrialisation and series production readiness.

Partnership Outcomes:

- Strengthened the client’s ability to demonstrate system performance to OEM partners.

- Established Datalink as a trusted engineering partner for high-performance automotive electronics development.

- Demonstrated Datalink’s end-to-end capability in concept design, prototyping, and technical validation.