- Home

- /

- Case Studies

- /

- How Datalink Electronics Developed a Direct Gold Finish Process Meeting IPC Class 3 and J-STD Standards for High-Reliability Electronics

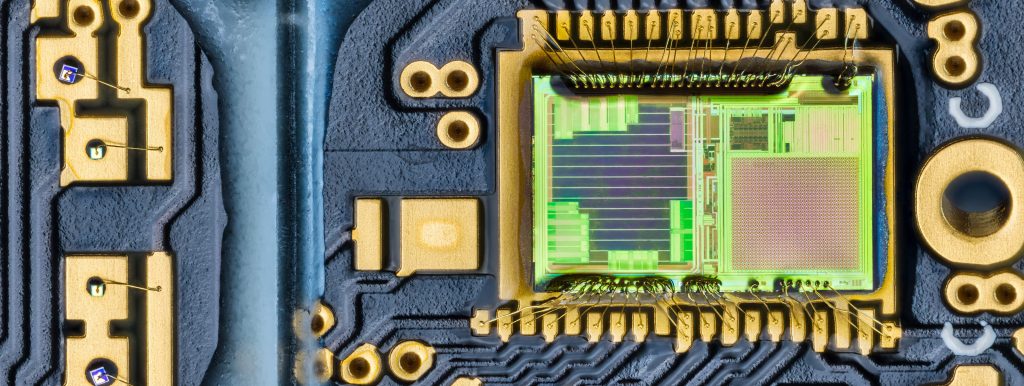

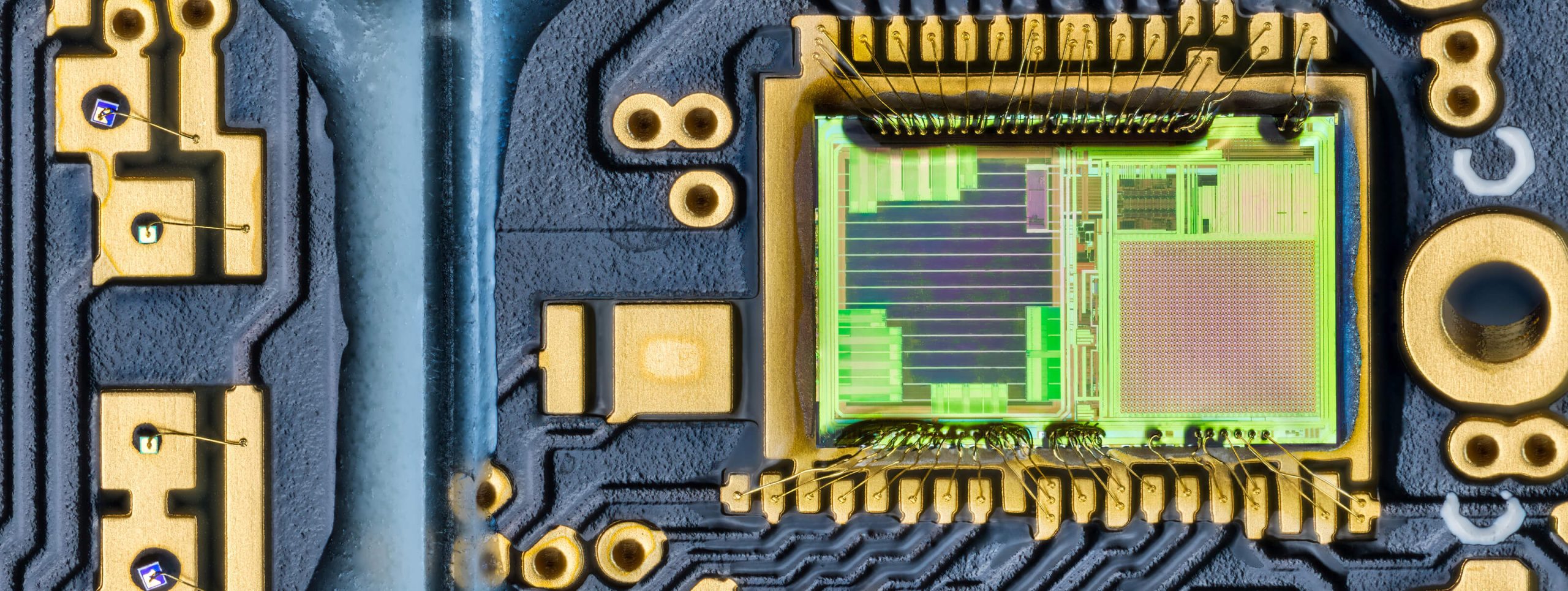

How Datalink Electronics Developed a Direct Gold Finish Process Meeting IPC Class 3 and J-STD Standards for High-Reliability Electronics

Client Profile / Background

The existing ENIG (Electroless Nickel Immersion Gold) process used across several assemblies was introducing minor issues with:

- Variable contact resistance, affecting low-level analogue signal consistency.

- Potential nickel diffusion over time, impacting solderability and conductivity.

- The need for improved surface durability in high-cycle connector and sensor applications.

The client’s goal was to achieve a direct gold deposit on copper to enhance electrical and mechanical performance — without compromising manufacturability, adhesion, or compliance with IPC Class 3 reliability standards.

Datalink’s engineering and process team conducted a comprehensive development and qualification programme to create a controlled, repeatable direct gold plating process suitable for high-reliability products.

Key Elements of the Solution:

- Process Design & Validation: Datalink developed and refined the gold deposition chemistry and pre-treatment stages, ensuring consistent adhesion, uniform thickness, and compatibility with downstream soldering and bonding.

- Surface Preparation & Cleanliness: Introduced enhanced substrate preparation methods to meet J-STD-001 cleanliness and solderability criteria, preventing contamination and oxidation.

- Precision Control & Monitoring: Integrated in-process measurement and bath analytics to ensure tight plating tolerance and repeatability across batches.

- Testing & Qualification: Validated the new process through cross-sectional analysis, adhesion testing, solder joint evaluation, and contact resistance measurement , all benchmarked to IPC-A-600 and IPC-A-610 Class 3 acceptance criteria.

- Documentation & Traceability: Fully documented process parameters, inspection steps, and operator certifications under ISO 9001 and IPC/J-STD compliance frameworks.

The result was a robust, production-ready direct gold finish process that offered measurable improvements in conductivity, solderability, and product life.

- Feasibility & Comparison:

Baseline testing against ENIG and OSP finishes confirmed the potential performance gains of direct gold in both electrical and environmental stability. - Prototype Runs:

Datalink produced controlled prototype panels for plating validation, measuring thickness uniformity, wetting balance, and solder joint reliability per J-STD-001 standards. - Qualification & Approval:

Detailed qualification data was reviewed with the client’s quality and design teams, confirming IPC Class 3 compliance across all tested parameters. - Production Integration:

The process was introduced into live product builds, complete with automated inspection, bath monitoring, and quality checkpoints . - Continuous Improvement:

Datalink maintains statistical process control (SPC) and continuous improvement reviews to ensure long-term stability and performance consistency.

The Results / Outcomes

- Achieved superior conductivity and corrosion resistance, eliminating nickel diffusion risks.

- Improved solderability and wire bond integrity under J-STD and IPC Class 3 conditions.

- Delivered consistent plating thickness and adhesion within tight tolerances.

- Enhanced mechanical durability for connector mating and cyclic test applications.

Operational & Quality Outcomes:

- Seamlessly integrated into production without increased process time or cost.

- Zero process non-conformances recorded across validation and first production runs.

- Strengthened customer confidence through traceable documentation and standards compliance.

- Established Datalink as a trusted supplier of advanced surface-finishing processes for high-reliability applications.